Unlocking Innovation: The Role of Rapid Prototyping Suppliers in Modern Manufacturing

In today's fast-paced manufacturing environment, innovation and adaptability are crucial for maintaining a competitive edge. One of the key elements enabling businesses to achieve these goals is the collaboration with rapid prototyping suppliers. These suppliers play an essential role in the product development lifecycle, making it possible for companies to turn concepts into tangible products swiftly and efficiently.

What is Rapid Prototyping?

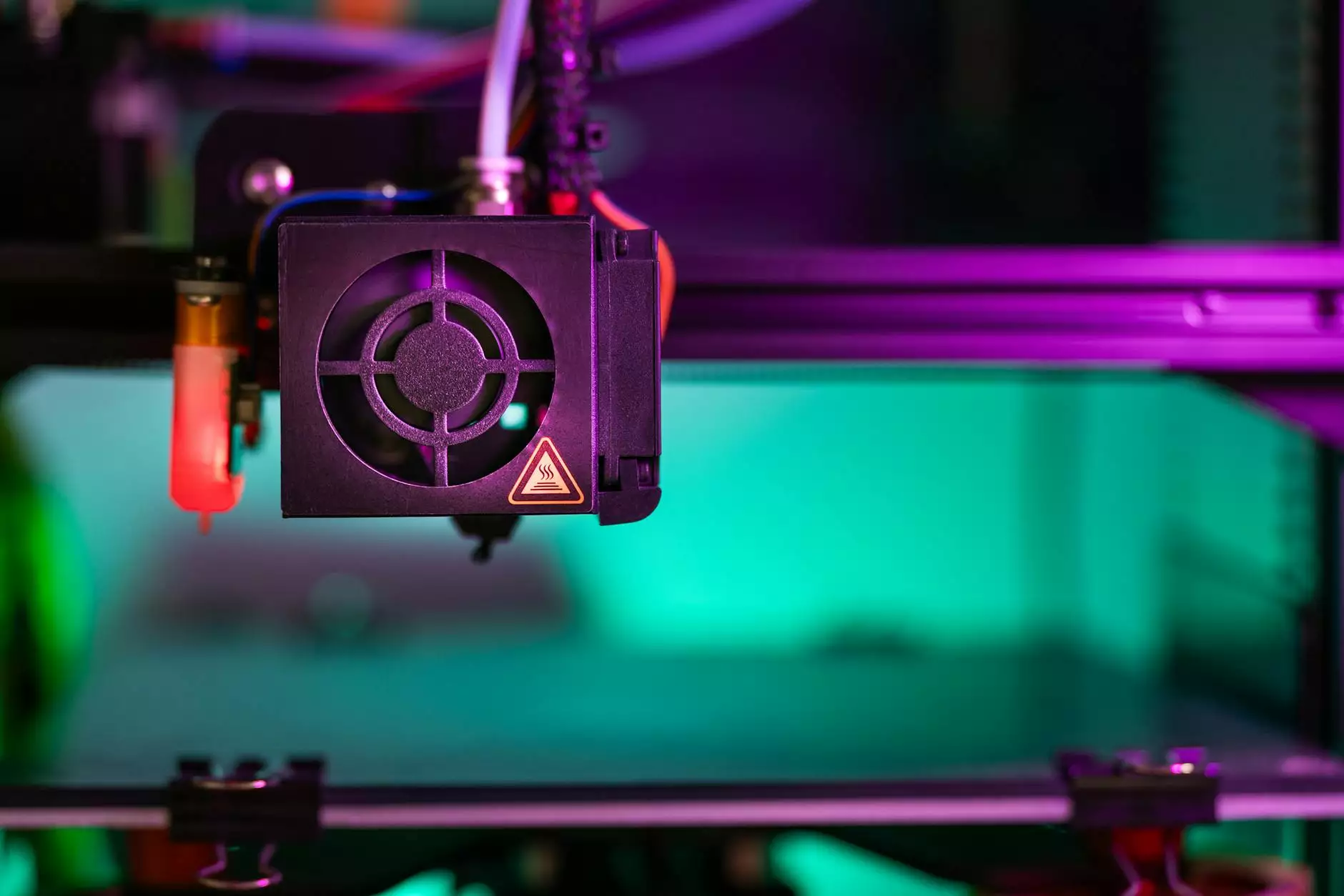

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer-aided design (CAD) data. This process allows businesses to visualize and test their products before entering full-scale production. Rapid prototyping suppliers specialize in providing the resources and technologies necessary for this critical development phase.

Benefits of Partnering with Rapid Prototyping Suppliers

Utilizing rapid prototyping suppliers offers several advantages that can significantly enhance your business operations:

- Speed to Market: The ability to rapidly create prototypes accelerates product development timelines, allowing businesses to launch products faster.

- Cost Efficiency: Early identification of design flaws can save companies substantial amounts of money by reducing costly revisions during later stages of production.

- Enhanced Collaboration: Prototyping fosters better communication among stakeholders, as teams can visualize concepts and provide immediate feedback.

- Testing and Validation: Prototypes can be tested under real-world conditions, leading to more effective product designs that meet user needs.

- Flexibility and Iteration: The ability to modify prototypes quickly enables design teams to iterate effectively based on testing results and user feedback.

Choosing the Right Rapid Prototyping Supplier

Selecting the right rapid prototyping supplier is crucial for maximizing the benefits of rapid prototyping. Here are key factors to consider:

Expertise and Experience

Look for suppliers with a proven track record in your industry. Experience ensures they understand specific challenges and requirements.

Technology and Capabilities

Evaluate the technology they use. Advanced 3D printing techniques (such as SLA, SLS, and FDM) can offer different benefits and materials suited for various applications.

Turnaround Time

Assess how quickly they can deliver prototypes. Speed is critical in the prototyping stage.

Quality Assurance

Ensure the supplier follows strict quality control protocols to maintain high standards in their prototypes.

Customer Support and Collaboration

Strong customer support can make a significant difference. A good partner will provide consultation and be responsive to your needs.

Case Studies: Transformation through Rapid Prototyping

To illustrate the impact of rapid prototyping suppliers, let’s explore a couple of case studies:

1. Automotive Industry

One leading automotive manufacturer partnered with a rapid prototyping supplier to develop a new line of eco-friendly vehicles. By rapidly creating and testing prototypes, they identified design flaws early in the process, leading to a 30% reduction in development costs and a quicker time to market.

2. Consumer Electronics

A startup in the consumer electronics space utilized rapid prototyping to develop a smart home device. The supplier's advanced 3D printing capabilities allowed them to produce multiple iterations in a matter of days. This agility enabled the startup to secure investor funding based on tangible prototypes rather than concept sketches, showcasing the product's potential effectively.

The Future of Rapid Prototyping in Business

The future of rapid prototyping looks bright, with technological advancements continuing to reshape the field. Emerging technologies such as artificial intelligence and machine learning are expected to enhance the prototyping process further. Here's what to expect:

1. Greater Customization

As 3D printing technology evolves, the ability to create highly customized products will become more prevalent, allowing businesses to cater specifically to consumer preferences.

2. Integration with Internet of Things (IoT)

Rapid prototyping will increasingly interface with IoT technologies, enabling smarter prototypes capable of real-time data collection and analytics, thus enhancing design processes.

3. Sustainable Practices

With a rising emphasis on sustainability, rapid prototyping suppliers are likely to adopt more eco-friendly materials and processes, contributing to greener manufacturing practices.

The Role of DeepMould in the Metal Fabrication Sector

As a leading player in the metal fabrication industry, DeepMould recognizes the essential link between rapid prototyping and effective manufacturing. By integrating services from rapid prototyping suppliers, DeepMould enhances its production capabilities, allowing clients to experience:

- Stronger Products: Metal prototypes help in assessing durability and structural integrity before mass production.

- Innovative Designs: Engineers at DeepMould can use rapid prototyping to experiment with new designs that push the boundaries of traditional manufacturing.

- Cost-Effective Solutions: Clients benefit from reduced waste and optimized production processes, thanks to iterative prototyping.

Conclusion

The integration of rapid prototyping suppliers into business practices is not just a trend; it's an essential strategy for modern manufacturing. The ability to develop products quickly and efficiently while minimizing costs provides a clear competitive advantage. Companies like DeepMould are leading the charge in the metal fabrication sector by embracing these innovations. In today's market, if you aspire to remain ahead, collaborating with rapid prototyping suppliers is not only advisable but imperative.

In conclusion, understanding and utilizing the benefits provided by rapid prototyping suppliers will empower businesses to innovate, adapt, and thrive in an ever-changing landscape. The future of manufacturing is undoubtedly intertwined with the advancements in prototyping technologies.